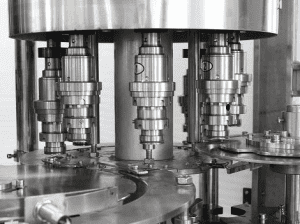

Makina odzaza chakumwa cha kaboni

Funsani Tsopanomakina odzaza zakumwa za carbonated-Makhalidwe

1. Makina odzazitsa zakumwa zamtundu uwu amaphatikiza kuchapa, kudzaza ndi ntchito za rotary capping mu unit imodzi.Ndi chida chodziwikiratu komanso chokwera kwambiri chamadzimadzi.

2. Makina odzaza chakumwa cha kaboni ndi oyenera kunyamula chakumwa chokhala ndi mpweya. Makina odzazitsa chakumwa cha kaboni ndi monga kutsatira mbali zonse, mwachitsanzo, ma valve odzaza, omwe amalumikizana mwachindunji amapangidwa ndi chitsulo chosapanga dzimbiri kapena zinthu zopanda vuto. Choncho zimagwirizana ndi zofunikira za Food ukhondo. Zigawo zosindikizira zimapangidwa ndi mphira wotsimikizira kutentha, kuti akwaniritse zofunikira za ogwiritsa ntchito kuti asatseke kutentha kwambiri.

3. Makina odzazitsa zakumwa za kaboni Pogwiritsa ntchito chowongolera chokhazikika kuti muzitha kuwongolera zokha kuchokera pamabotolo omwe amalowa mpaka kumaliza kunyamula, makina odzaza zakumwa za kaboni Pogwiritsa ntchito transducer ngati chowongolera liwiro, kuti wogwiritsa ntchitoyo amatha kuwongolera makinawo mosavuta kuti agwirizane ndi mphamvu zosiyanasiyana, Kutengera mfundo yofananira yodzaza. ndi ma valve amasiku ano a kasupe kuti atsimikizire chakumwa chakumwa, Kugwiritsa ntchito maginito otsogola kuwongolera torque ya cap-screwing torque, kuti mutsimikizire khalidwe.

Technical parameter

| Chitsanzo | Chithunzi cha DCGF 16-12-6 | Chithunzi cha DCGF 18-18-6 | Chithunzi cha DCGF 24-24-8 | Chithunzi cha DCGF 32-32-10 | Chithunzi cha DCGF 40-40-12 | Chithunzi cha DCGF 50-50-15 |

| Kuchapa No | 16 | 18 | 24 | 32 | 40 | 50 |

| Kudzaza No | 12 | 18 | 24 | 32 | 40 | 50 |

| Capping No | 6 | 6 | 8 | 10 | 12 | 15 |

| Mphamvu Yopanga (500ml) | 3000 BPH | 5000 BPH | 8000BPH | 12000 BPH | 15000 BPH | 18000 BPH |

| Ikani Mphamvu (KW) | 3.5 | 4 | 4.8 | 7.6 | 8.3 | 9.6 |

| Kukula konse | 2450 × 1800 × 2400 pa | 2650 × 1900 × 2400 pa | 2900 × 2100 × 2400 pa | 4100 × 2400 × 2400 pa | 4550 × 2650 × 2400 pa | 5450 × 3210 × 2400 pa |

1. Kugwiritsa ntchito mphepo anatumiza mwayi ndi kusuntha gudumu mu botolo mwachindunji chikugwirizana luso; zolephereka wononga ndi unyolo conveyor, izi zimathandiza kusintha botolo kukhala kosavuta.

2. Kutumiza kwa mabotolo kutengera ukadaulo wa clip bottleneck, kusintha kooneka ngati botolo sikufunikira kusintha mulingo wa zida, kusintha kokha kokhudzana ndi mbale yopindika, gudumu ndi zida za nayiloni ndizokwanira.

3. Chojambula chopangidwa mwapadera chopangidwa ndi chitsulo chosapanga dzimbiri chotsuka botolo ndi cholimba komanso chokhazikika, palibe kukhudza ndi wononga malo a pakamwa pa botolo kuti apewe kuipitsidwa kwachiwiri.

4. Silinda imayendetsa valavu mayendedwe ndi olondola komanso odalirika. Valavu yodzaza kwambiri, yolondola kwambiri, yodzaza mwachangu komanso yolondola. Okonzeka ndi CIP loop ndi njira zowongolera, zidazo ndizosavuta kuyeretsa.

5. Spiraling kuchepa pamene linanena bungwe botolo, kusintha botolo mawonekedwe palibe kusintha kutalika kwa unyolo conveyor.

6. Kugwiritsa ntchito chowongolera chokhazikika ngati malo owongolera; pogwiritsa ntchito ma transmitter, ma elekitiromagineti kuyeza kuti madzi azikhala bwino kuti atsimikizire kukhazikika kwamadzimadzi.

7. Valavu yatsopano yodzazira, gasi wobwerera ndi madzi odzaza ndizosiyana kuti zitsimikizire kuti zida zodzaza ndi zoyera.

8. Makinawa amatengera chivundikiro chapamwamba cha maginito clutch screw ndipo torque ya torsion imatha kusintha, kotero kuti screwing ndi yotetezeka komanso yodalirika.

Mankhwala Analimbikitsa

Zambiri +- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur